PRESS BRAKE

PRESS BRAKE

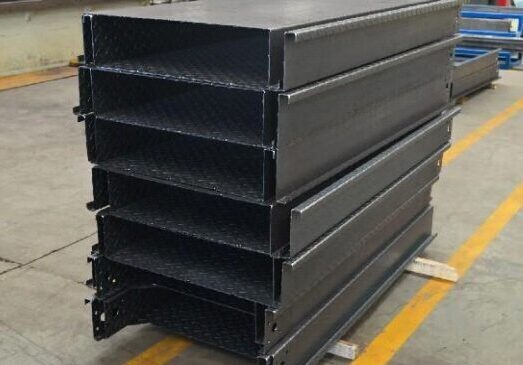

HIGH STRENGTH MACHINE BED

- The tensile and compressive strength of the main structure, as well as the deflection of the tabletop’s parallel lines, all fall within the safe operating range.

The machine is constructed using Q235B steel plates, with grooved joints to enhance overall structural integrity.

The entire frame undergoes annealing and stress relief treatment to ensure rigidity, strength, precision, and long-term stability.

- A high-precision gantry milling machine performs one-pass processing to guarantee the parallelism and perpendicularity of all mounting surfaces.

VERTICAL PLATE COMPENSATION SYSTEM

- Developed by a specialized technical team, the rack wall panel deformation compensation system utilizes a “C”-shaped frame that operates independently from the main rack wall structure.

- Equipped with a dedicated automatic adjustment and balancing device, the system effectively prevents position feedback errors from the grating ruler – errors that may result from wall panel deformation during the bending process.

This ensures consistent bending accuracy, even under reactive forces.

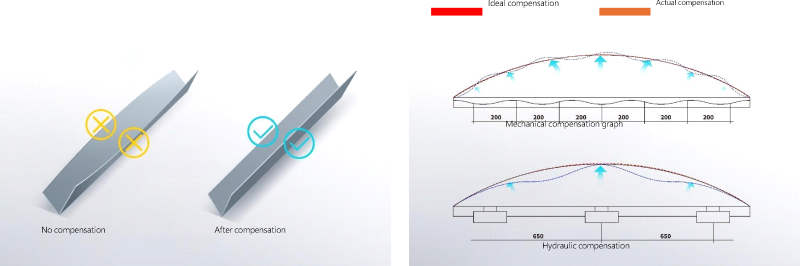

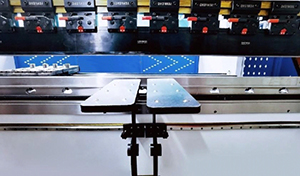

DEFLECTION COMPENSATION SYSTEM

It consists of uniquely processed and heat-treated wedge blocks.

Each group of wedge blocks is engineered to provide relative displacement compensation based on the force and deformation experienced by the upper and lower beams during operation.

The CNC system calculates the required compensation for both beams according to the load force applied during bending.

It then automatically controls the relative movement of the wedge blocks, effectively correcting deflection and deformation in the upper and lower beams.

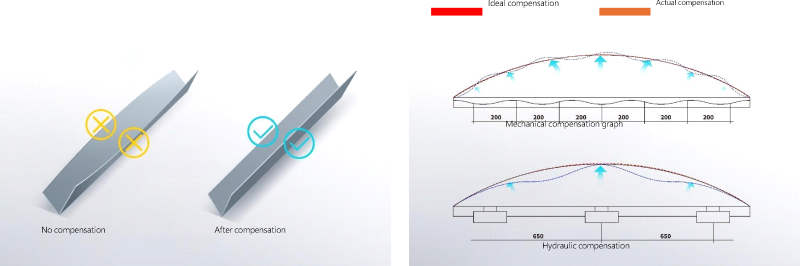

DEFLECTION COMPENSATION SYSTEM

It consists of uniquely processed and heat-treated wedge blocks.

Each group of wedge blocks is engineered to provide relative displacement compensation based on the force and deformation experienced by the upper and lower beams during operation.

The CNC system calculates the required compensation for both beams according to the load force applied during bending.

It then automatically controls the relative movement of the wedge blocks, effectively correcting deflection and deformation in the upper and lower beams.

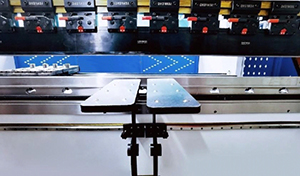

FRONT DRAG MODULE

- The front support rack is mounted on rollers that glide along a linear guide rail in the Z-axis direction, allowing smooth manual adjustment left and right.

- Height adjustment is easily achieved via a convenient handle.

- Optional extended beams with designated parking positions are available for the support rack, based on specific requirementS.

GERMAN MADE HYDRAULIC SYSTEM

- High-frequency response (12 ms) enables fast and easy debugging

- Built-in integrated amplifier for compact and efficient performance

- Integrated precision position feedback sensor ensures accurate monitoring

- Closed-loop control delivers superior accuracy

- Flow control curve offers enhanced linearity

- Minimal pressure loss and low heat generation for improved efficiency

FRONT DRAG MODULE

- The front support rack is mounted on rollers that glide along a linear guide rail in the Z-axis direction, allowing smooth manual adjustment left and right.

- Height adjustment is easily achieved via a convenient handle.

- Optional extended beams with designated parking positions are available for the support rack, based on specific requirements.

GERMAN MADE HYDRAULIC SYSTEM

- High-frequency response (12 ms) enables fast and easy debugging

- Built-in integrated amplifier for compact and efficient performance

- Integrated precision position feedback sensor ensures accurate monitoring

- Closed-loop control delivers superior accuracy

- Flow control curve offers enhanced linearity

- Minimal pressure loss and low heat generation for improved efficiency

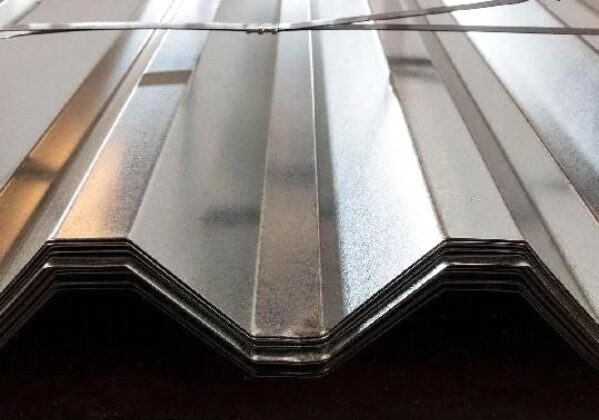

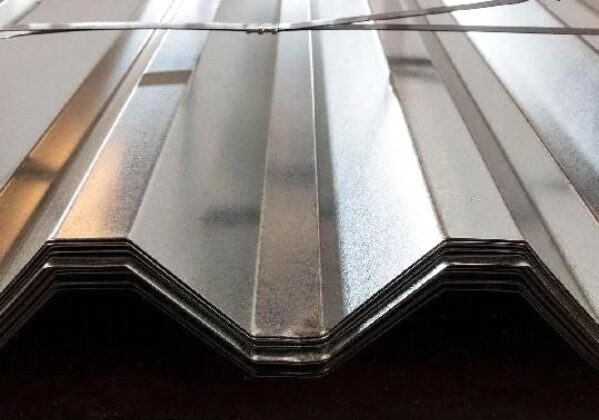

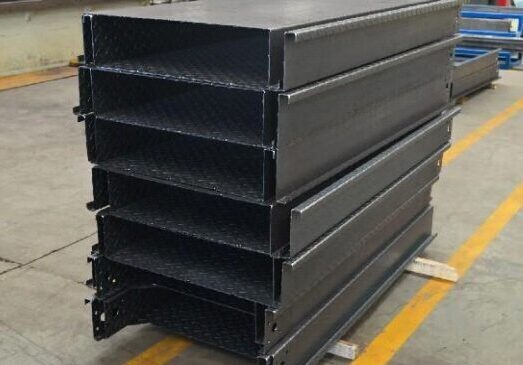

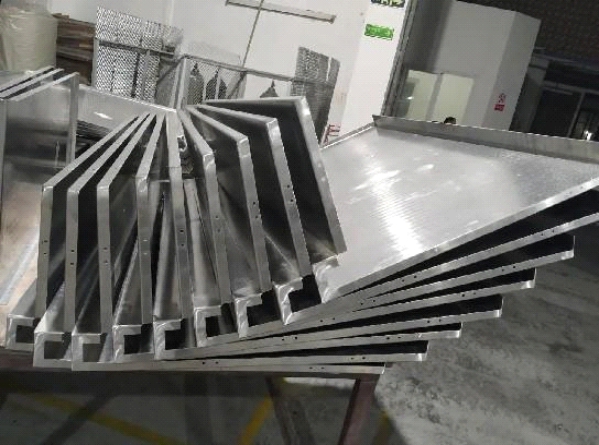

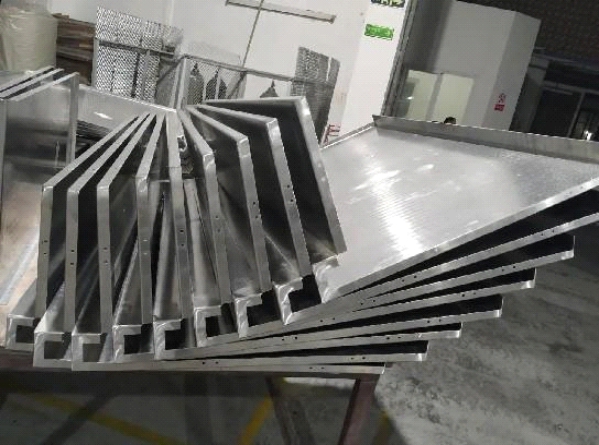

ALUMINIUM

STAINLESS STEEL

CARBON STEEL

ALUMINIUM

STAINLESS STEEL

CARBON STEEL

ZINC

ALUMINIUM

COPPER

ZINC

ALUMINIUM

COPPER